측정솔루션

가스센서

What is the purpose of the measurement?

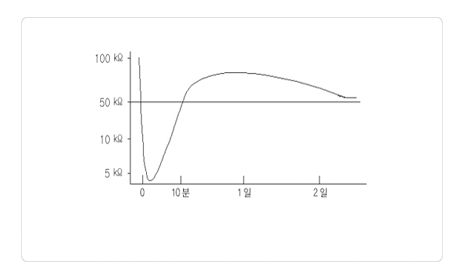

- Gas sensor sensitivity : Change in resistance

- Reaction Rate : Degeneration and recovery time

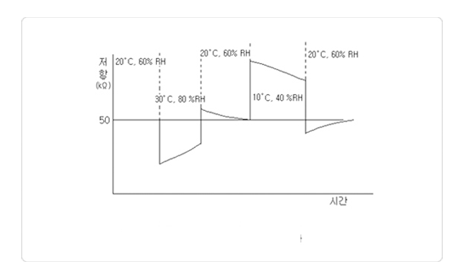

- Response to various environmental changes : Gas concentration, Temperature, Humidity Setting time of the initial resistance value of the sensor

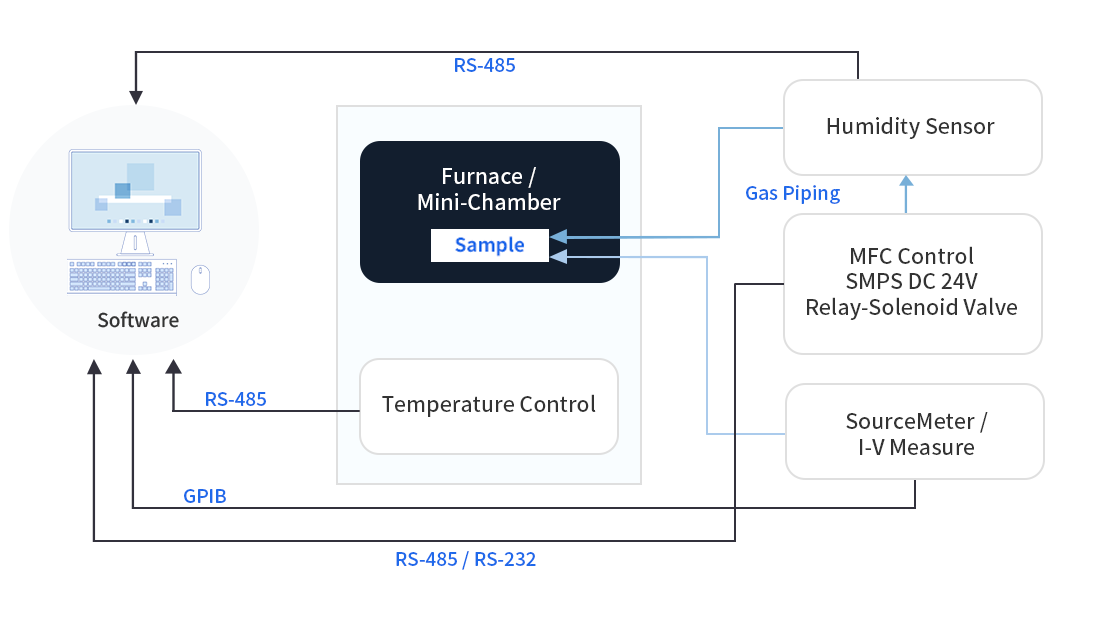

System integration using multiple devices

Resistance Range from Ω ~ GΩ

Monitoring the change of resistance according to the change of gas content and temperature

Optionally, a humidity configuration is added Monitoring resistance variation according to humidity change.

Consists of various conditions in a sequence MFC(Gas Flow), Temperature, Duration Time

가스센서 시스템

가스센서 특징

-

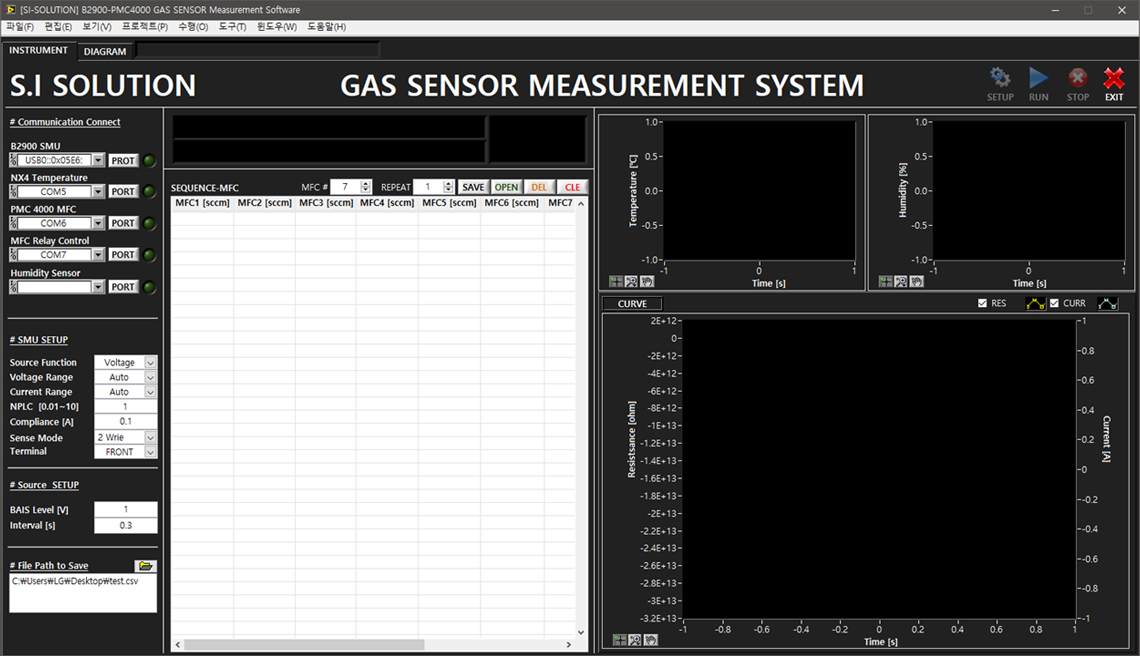

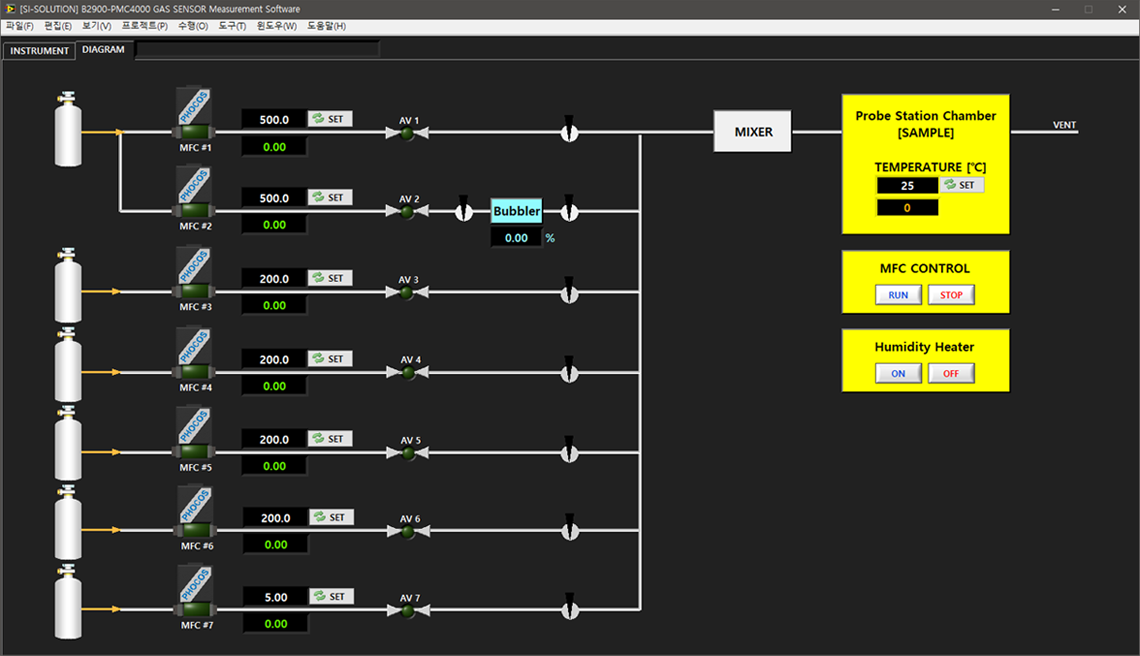

프로그램 주요 특징

- MFC 유량, 온도를 시퀀스로 설정이 가능 (시퀀스 저장 및 불러오기 가능)

- 온도, 습도, 유량, 저항의 변화를 시퀀스의 순서대로 실시간 모니터링

- 실시간 측정 Data 저장 가능

- MFC, 온도, 습도, Valve 컨트롤 가능

- Diagram 을 통한 진행상태 확인

- Customized Software 개발 가능

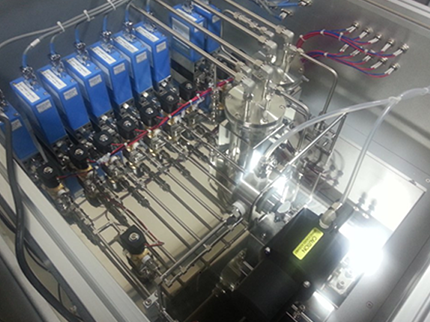

MFC: PMC-4000

-

MFC: PMC-4000

- Input/Output VDC 0~5V (<0.5%)

- 4 digit LED Display

- 1 to 6 Channel (Expandable up to 8 Channels)

- RS-485

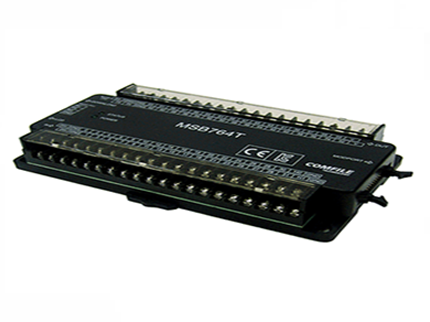

Valve Relay: Compile MSB624RA-DC

-

Valve Relay: Compile MSB624RA-DC

- Power DCV 24V (Use with SMPS 24V)

- 8 Relays (Connect Solenoid Valve)

- RS-232

Furnace Lindberg

-

Furnace Lindberg

- Up to 1100℃ (TC K type)

- Split-hinge design simplifies

- Safety switch disconnects power when furnace is opened

- RS-485

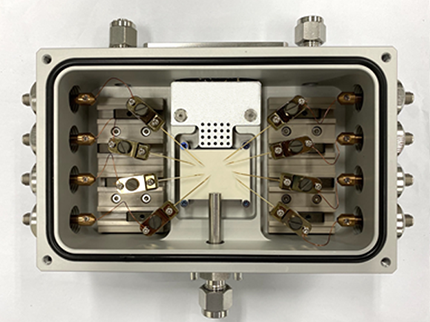

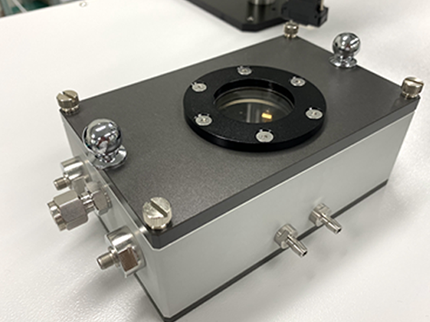

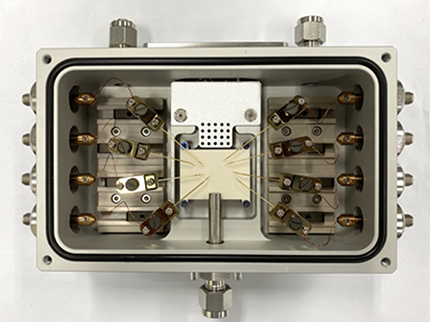

Mini Chamber MPS4000

-

Mini Chamber MPS4000

- Up to 900℃ (TC K type)

- Tungsten Probe (Gold Plated), Tip Adaptor (Cu-Gold Plated)

- Connector Type SMA

- RS-485

Keithley 2636 SMU

-

Keithley 2636 SMU

- 20W DC, 200mV to 200V, 100pA to 1A

- Source and sink (4-quadrant) operation

- 6½-digit resolution

- TSP Link expansion technology for multi channel

- USB 2.0, LXI-C, GPIB, RS-232, and digital I/O interfaces